Reverse Engineering

REVERSE ENGINEERING

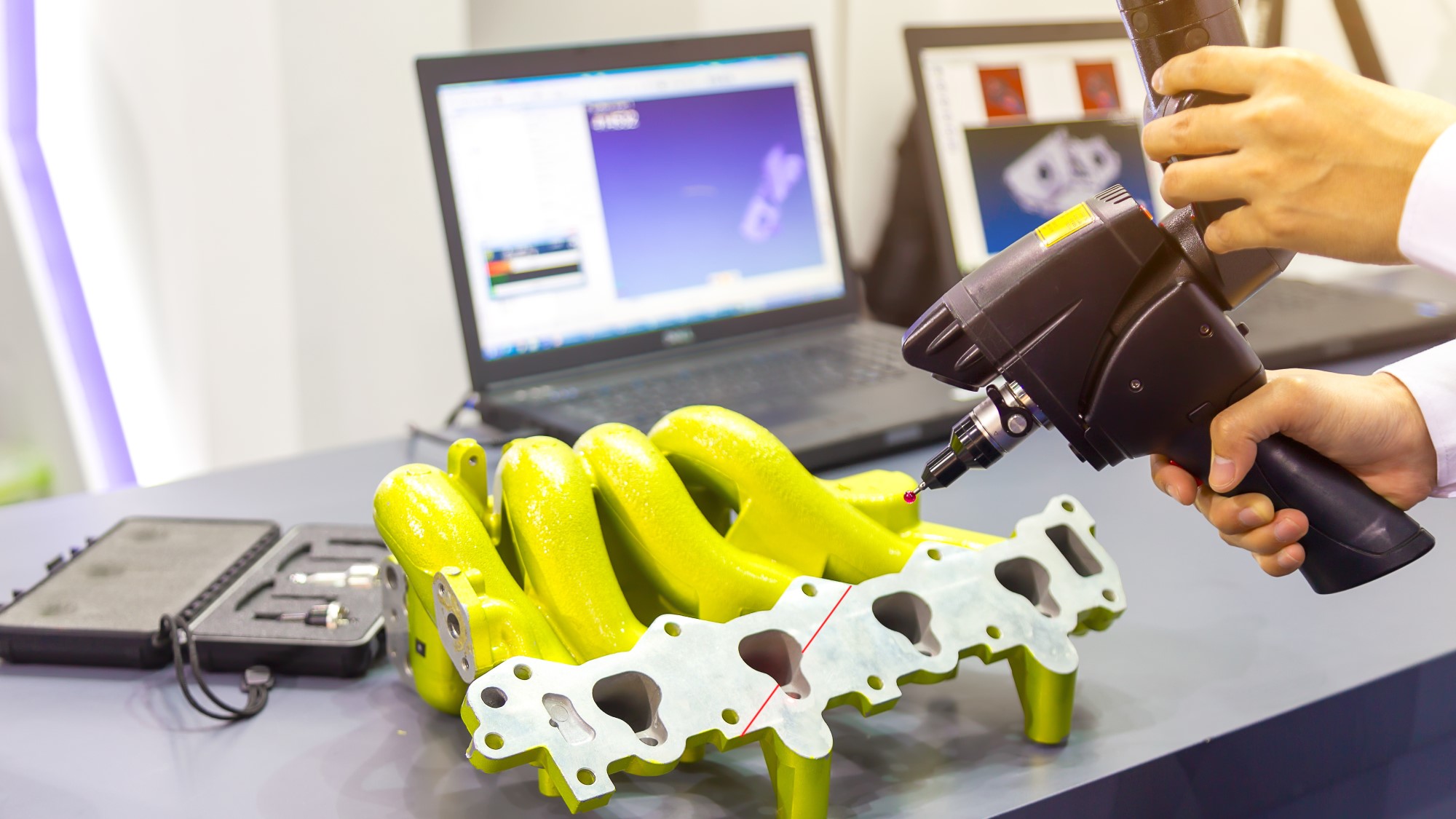

The process of creating a CAD model for reverse engineering services starts with Laser scanning and CMM data generation and require some understanding of the original designer’s thought process. We are capable of measuring a variety of components and assemblies both large and small. Measurement strategies include both tactile and non-contact scanning in the form of touch trigger probing and laser scanning. Scan data is used to create 3D CAD models for use in design and development activities. Our reverse engineering team helps us to create quick drawings from old parts and templates.

Reverse Engineering refers to the process of re-creating design drawings by taking measurements and/or scans of the part itself.

It’s a simple, two-step process:

Scan the object

Create a 3D model of the object

Our core expertise as follows:

3D Laser Scanning

Computer- Aided Verification (CAV)

Modeling Support

Part Digitization

3D Scan Data to Parametric Models

STL Files to Parametric Models

We also provide Inspection services which help you to reduce risk, ensure quality and accuracy, as well as meeting regulatory requirements.