Services

Product Design

Our design process begins after interacting with our clients and thoroughly reviewing their objectives and design requirements. Our Design team then works together to generate a series of concept sketches and all concepts are evaluated by the client across every phase of the design process and refined based on their feedback to produce a final design direction. Our process starts from market analysis to goes up to the final product launch. We will combine creative vision, technical expertise, and our design skills to help you develop a product and get where you need to be.

With our design parameters and deep knowledge, we transform ideas into engineering drawings, concept to detailed design, development to simulation by adhering international standards.

SANQ multi-disciplinary design solutions for the following:

3D Modeling & 2D Drafting

Engineering Drawings & Detailing

Complex Surface Modeling

New Product Development

Geometric Dimensioning & Tolerancing (GD & T)

Legacy Data Conversion & Migration

Engineering Change Management

Design Optimization

Parametric / Non Parametric Designing

Exploded Views for Assemblies

Custom Part Libraries

Creating Manufacturing / Fabrication Drawings

Detailing for Fixture Designing

Assembly Animations

Visualization

Technical Documentation

Tooling Design (Fixture/ Dies/Pattern)

BIW Design

Front End Engineering Design (FEED)

Analysis

SANQ is specialized in various design validation and performance check under severe loading conditions. The wide range of simulation and the computational engineering solutions offers high quality results by reducing the cost and timeframe of the products by enabling constructive designs and conceptual drawings.

Computer Aided Engineering are the possible ways to forecast and quantify the effects of real-world conditions on a part or assembly and helps to test complex geometry and the ability to capture local effects acting on a small area of the design.

Our wide range of services as follows:

FEA

Structural Analysis (Linear, Non-linear)

Thermal Analysis (Steady State and Transient)

Noise, Vibration, Harshness Analysis (NVH Analysis)

Crash / Impact Analysis

Durability Analysis

Contact Stress Analysis

Dynamic validation

Composite Analysis

Fatigue, Fracture & Vibrational Analysis

Static and Dynamic Analysis

Modal Analysis

Buckling Analysis

Multi-body Dynamic Analysis

CFD

Simulation of Internal & External Fluid Flow Analysis

Heat Transfer Analysis

Multiphase Flow Analysis

Mold Flow Analysis

Hydrodynamic Analysis

Thermodynamic Analysis

Combustion Analysis

Turbo Machinery Analysis

Aerodynamic Analysis

Fluid-Structure Interaction Analysis

API CAD CUSTOMIZATION

Design Automation provides excellent way of automating repetitive tasks thereby ensuring timely delivery of projects and more focus on new opportunities and development tasks. We can provide end-to-end design automation solutions for the engineering design process.

A simple minor customization of your CAD, CAM or CAE application and automation of your repetitive manual procedures could save up to 95% of your time and have a tremendous impact on your productivity.

Many repetitive procedures and routine steps in your design and manufacturing process can be automated. Customization of CAD helps customers to do things faster, efficient and accurate.

Our wide range of services as follows:

CAD –PDM or SAP Integration Tools

CAD -DB (SQL Server) Integration Tools

CAD Software Development

Product / Sales Configurator Development

Development of Product Variants

Development of Knowledge Based Tools

Design Automation (API Programming for CAD/PDM)

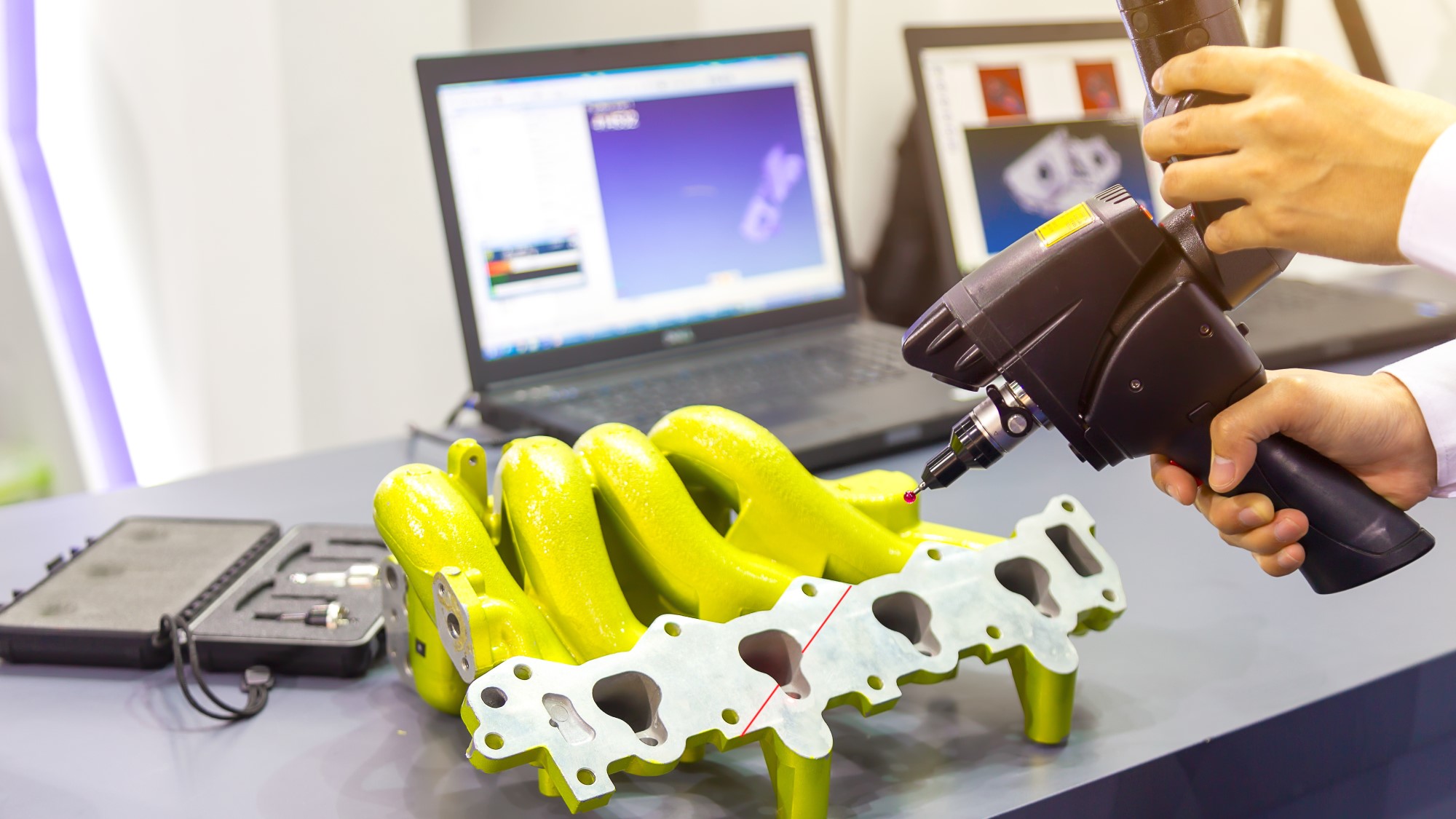

REVERSE ENGINEERING

The process of creating a CAD model for reverse engineering services starts with Laser scanning and CMM data generation and require some understanding of the original designer’s thought process. We are capable of measuring a variety of components and assemblies both large and small. Measurement strategies include both tactile and non-contact scanning in the form of touch trigger probing and laser scanning. Scan data is used to create 3D CAD models for use in design and development activities. Our reverse engineering team helps us to create quick drawings from old parts and templates.

Reverse Engineering refers to the process of re-creating design drawings by taking measurements and/or scans of the part itself.

It’s a simple, two-step process:

Scan the object

Create a 3D model of the object.

Our core expertise as follows:

3D Laser Scanning

Computer- Aided Verification (CAV)

Modeling Support

Part Digitization

3D Scan Data to Parametric Models

STL Files to Parametric Models

We also provide Inspection services which help you to reduce risk, ensure quality and accuracy, as well as meeting regulatory requirements.

Rapid Prototyping / Prototype Development

The prototype is an important milestone in product creation as it’s going to if your idea is viable and executable. Using the 3D Engineering model various rapid prototyping processes are considered for fabrication. The prototyping process involves producing functional full scale models of the product. The prototype must be evaluated for proper fitment of components, mechanism functionality, human factors, user experience and overall form.

Engineering revisions are made based upon the findings of the prototype testing and subsequent prototypes are produced to verify issue corrections to achieve optimal functionality. It is a lot easier to visualize something than it is to actualize it. You may have a great idea in mind but unless you can find someone to help you bring it to life, it’s not going to go much further than your imagination.

We help product design engineers to develop CAD prototypes for eliminating iterative design process for testing to help save time and cost.

Our Rapid Prototyping services includes:

3D Printing

Stereo Lithography(SLA)

Selective Laser Sintering(SLS)

Fused Deposition Modeling(FDM)

Direct Metal Laser Sintering(DMLS)

Manufacturing Support Services

Our Manufacturing Engineering Services operates in the industrialization phase to define the means of production and help optimize their manufacturing capability. We also participate in defining workflows and production lines and in developing industrial validation plans and piloting each step before production line-up. Our services can help you plan your manufacturing process so that you can reduce your time-to-market, effectively utilize manpower, optimize the use of materials and achieve quality standards.

We ensure well-accepted quality procedures and documentation standards are in place throughout the manufacturing services process. We integrate our diversified knowledge and experience with latest engineering technologies to support our clients in developing right solutions to meet specific production requirements. We take pride in assisting our clients from initial design process till the final product.

We render manufacturing services in following area:

Post Processor Customization

Tool Path Optimization

Multi-Axis Programming for Lathe, Mills & Turns

Wire EDM & CNC Router Programming

Sheet Metal Design

5 Axis Machining Programming

Process and Maintenance

Production Planning, Production Control and Operations.

Engineering, Fabrication & Assembly.

Design for Manufacturing (DFM)

Cost Impact / Machinability

Manufacturability Planning

CMM programming

Should Cost Analysis

CAM Programming Services

Value Engineering

Value Engineering is referred to an organized and systematic process used to analyze the functions of a product or process so as to improve the value of the same. Our unique process can help you enhance the functionality of your core operations thereby saving on cost and time. It promotes the substitution of materials and methods with less expensive alternative, without changing its functionality.

Our design optimization solutions bring cost saving and expedites product development processes with meeting the required targets in performance, reliability, quality, and safety.

VE / VA: ( Design Format – Will send reference )

Alternate Manufacturing Process

Weight Optimization

Material Substitution

Cost Reduction

Electrical & Electronics

We render end-to-end solutions across multiple industries. Our team supports the development of comprehensive systems that are compatible with low, medium and high voltage applications. With our hand-skilled expertise, we implement cost-effective, intuitive, robust solutions for electrical and electronics challenges.

We focus on cost optimization and qualitatively benchmarked embedded electronic equipment and electrical systems.

Electrical

PCB Design

Control Panel Design

Wire Harness Design

Electrical Schematics

Lighting Design and Analysis

Electronics

Analog Circuit Design

Digital Circuit Design

Microprocessor/Microcontroller Design

Wireless Circuit Designs

Communications Interface Designs

Control system architecture

Filed instrument location

Robo Programming

Robo Programming is used to perform autonomous tasks and automate, maintain and assemble the process which is useful for wide range of repetitive tasks for long productions runs resulting the increase of productivity, safety, efficiency, quality and consistency of the product with milli or micro inch accuracy.

We work with robotic systems to integrate robots with a wide variety of applications, such as:

Pick and place

Part and Product Manipulation

Line tracking

Drilling

Welding

Palletizing

Safety control

Routing

Painting & Polishing

De- Burring & De- Flashing

We work with robotic systems to integrate robots with a wide variety of applications, such as:

- Layout considerations for robotic systems

- Robotic systems integration safety regulations

- Robotic systems and humans interface / Interaction